estion: The armrest is abnormally hot during operation

1. The tension of the handrail is too tight or too loose or the guide bar is offset;

2. The interface of the guide device is not smooth, and the guide device is not on the same horizontal line;

3. The friction force of the driving wheel of the handrail is too tight or too loose, and the driving wheel is not in the center of the handrail;

4. The handrail entrance switch device is worn out.

If the above problems are solved, the fever will be alleviated. The handrail is operated by friction force, so there will be a little heat.

Question: The handrail falls off during operation

1. The model of the handrail is wrong, the lip is too large, which does not meet the requirements, or the rubber loses its performance after long-term operation. At this time, the handrail needs to be replaced;

2. The handrail is gradually stretched during long-term use, and the handrail needs to be re-tightened at this time;

3. The wings of the friction wheel are worn and loose, and need to be replaced;

4. The pressure belt wheel is worn and loose.

The operation of the handrail depends on the combination of multiple accessories, and the reasons for falling off can be checked one by one.

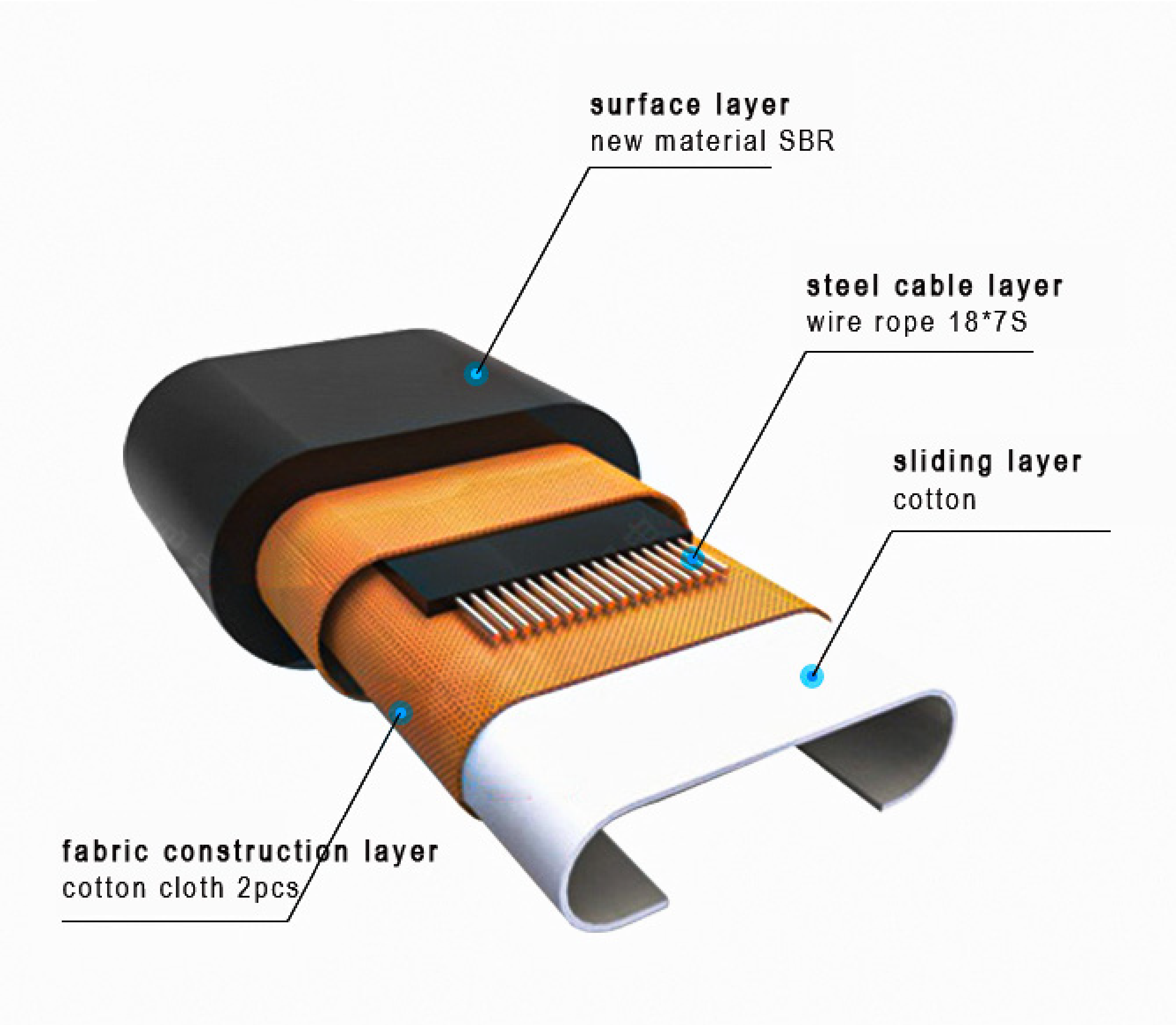

Question: The sliding layer of the handrail is worn and the steel wire is exposed

1. There are cracks on the surface of the friction wheel, which is easy to damage the sliding layer of the handrail through friction;

2. The friction wheel and the pressure belt wheel are not an acceleration, which is easy to damage the surface and sliding layer of the handrail;

3. The rotating sprocket group is damaged. At the arc of the handrail belt, the rotating sprocket group does not rotate. The sliding layer is rubbed for a long time, and the handrail belt is most likely to be damaged, so it is very important to choose a rotating chain;

4. The friction coefficient of the material of the sliding layer of the handrail is not large enough, which will cause the friction wheel and the handrail to slip and heat up, and wear the sliding layer.

Question: The surface of the handrail has scratches, lines, and serious wear

1. The bearing of the pressure belt wheel is damaged, the rotation pattern is different, or it does not rotate, and it directly contacts and rubs with the handrail belt, resulting in surface abrasion;

2. The entrance and exit of the escalator is damaged. Some escalators use the entrance and exit with hair. The hair is aging and cannot be replaced in time. Some escalators use the entrance and exit without hair.

3. Due to external factors, if there is friction at the entrance and exit, the surface of the handrail will be damaged.

Question: The lip of the handrail is worn and fluffed

1. The wear of the lip of the handrail is caused by the continuous operation of the handrail and friction with other accessories for a long time;

2. The fuzzing phenomenon must be eliminated, most of which are caused by the thorns in the welding of the guide rail joints;

3. The lip of the armrest is too large and swings back and forth, resulting in damage to the lip.

Question: Blisters appear on the surface of the handrail

1. The wear-resistant layer of the handrail is not effectively combined, resulting in stratification and bulging. The reason is that there is no compaction during the production process and the gas is not excluded;

2. The pressure is not uniform when the handrail is heat-cured and vulcanized, resulting in the gas not being removed;

3. The heating area is not uniform during thermosetting vulcanization, causing the problem of stratification;

4. The appearance of vesicles during use is due to oil pollution on the surface, resulting in changes in the stability of rubber properties;

5. The handrail driven by the linear system is prone to heat and cause rubber delamination and foaming.

The structure of the handrail determines the defects of the handrail. The handrail is an effective combination of rubber and cord. Due to thermosetting vulcanization, it cannot change the molecular structure of the cord, so it cannot form an inseparable whole. There must be gas hiding in the gap , so the handrail industry all over the world has not overcome the foaming factor of the handrail, and every manufacturer is trying to reduce the occurrence of the foaming problem.

Question: The surface of the handrail is cracked

Faults, cracks, and creases appear on the surface of the handrail, which are collectively referred to as cracks on the handrail. The main reason for the cracks is

Handrail rubber aging, due to long-term rubber exposure to heat, oxygen, light, mechanical force, radiation, chemical media, air

The effect of external factors such as ozone causes chemical changes in its macromolecular chains, destroying the original chemical structure of rubber,

As a result, the performance of the rubber deteriorates.

Post time: Mar-10-2023