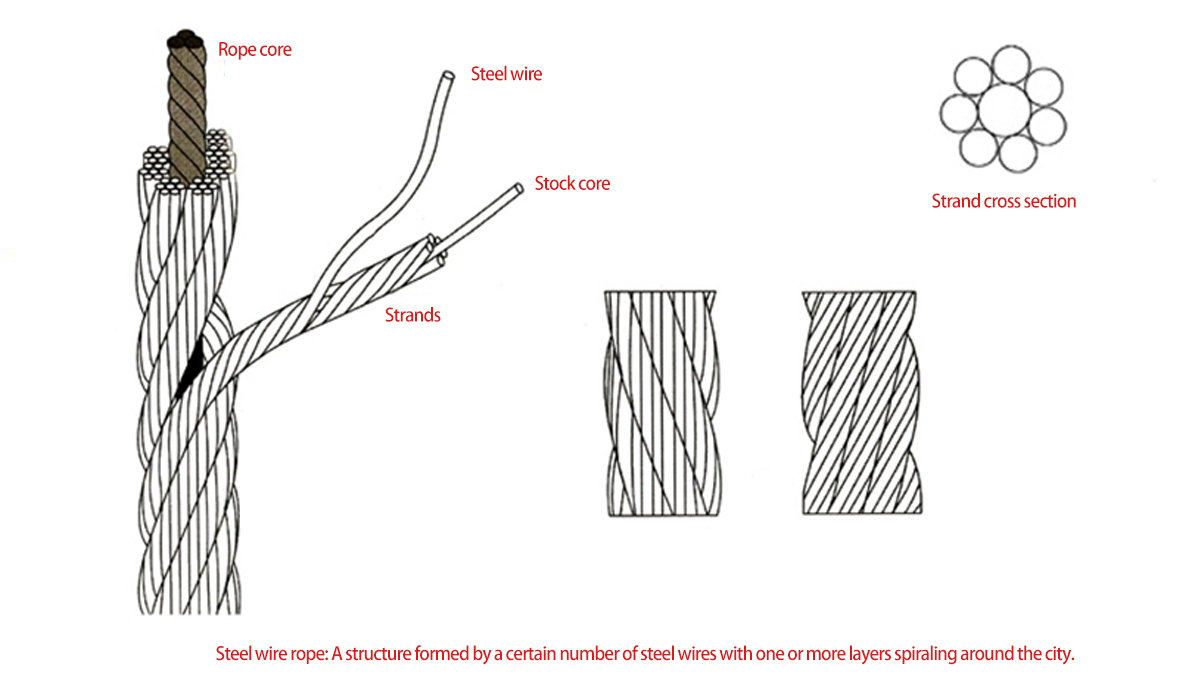

Elevator wire rope is a specially designed wire rope used in elevator systems to support and operate the elevator. This kind of steel wire rope is usually braided from multiple strands of steel wire and has high strength and wear resistance to ensure safe and reliable elevator operation. The selection and installation of special elevator wire ropes need to comply with strict industry standards and safety regulations to ensure the safety performance and reliability of the elevator system.

Exploded view of wire rope components

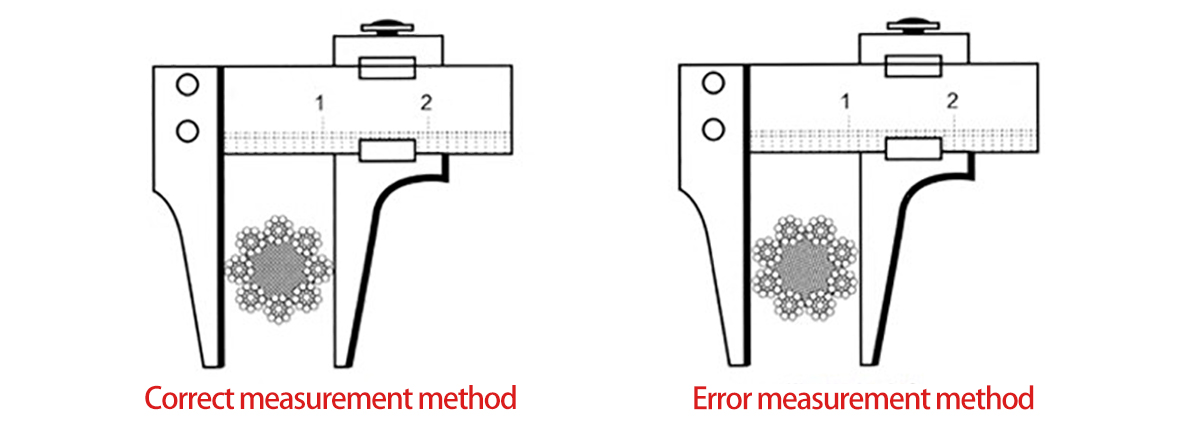

How to measure wire rope diameter

The correct method of measuring the wire rope is of great significance for the selection of the diameter of the wire rope and the accumulation of data on the change of the diameter of the wire rope during use. As shown in the figure below, whether the measurement method of steel wire diameter is correct or not, the measurement data obtained will be completely different.

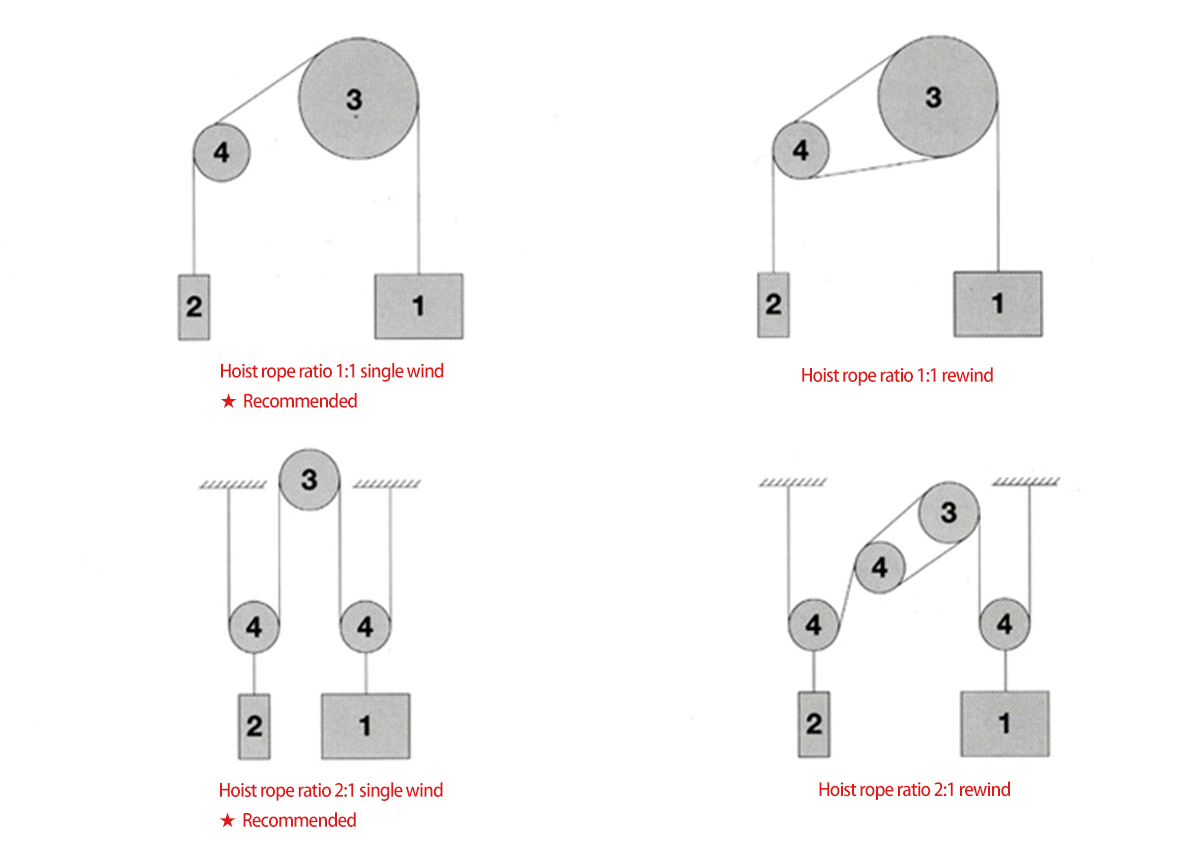

Traction method used by wire rope

1.Elevator car

2.Counterbalance

3.Traction wheel

4.Over-line pulley and directive wheel

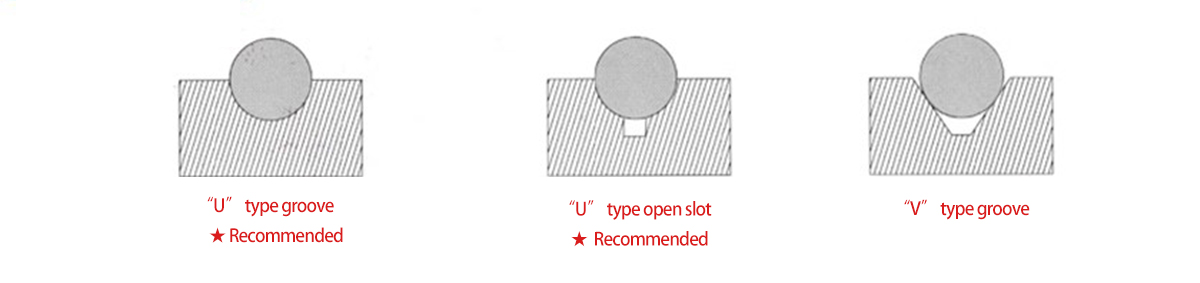

Traction sheave rope groove type

Storage and transportation

a) The wire rope should be stored in a dry, clean room. It is best to use pallets and other materials to pad the wire rope off the ground to prevent the wire rope from coming into contact with chemicals such as acids and alkalis. Open storage is strictly prohibited.

b) When transporting on the ground, the wire rope is not allowed to roll on the uneven ground, which may cause the surface of the wire rope to be crushed.

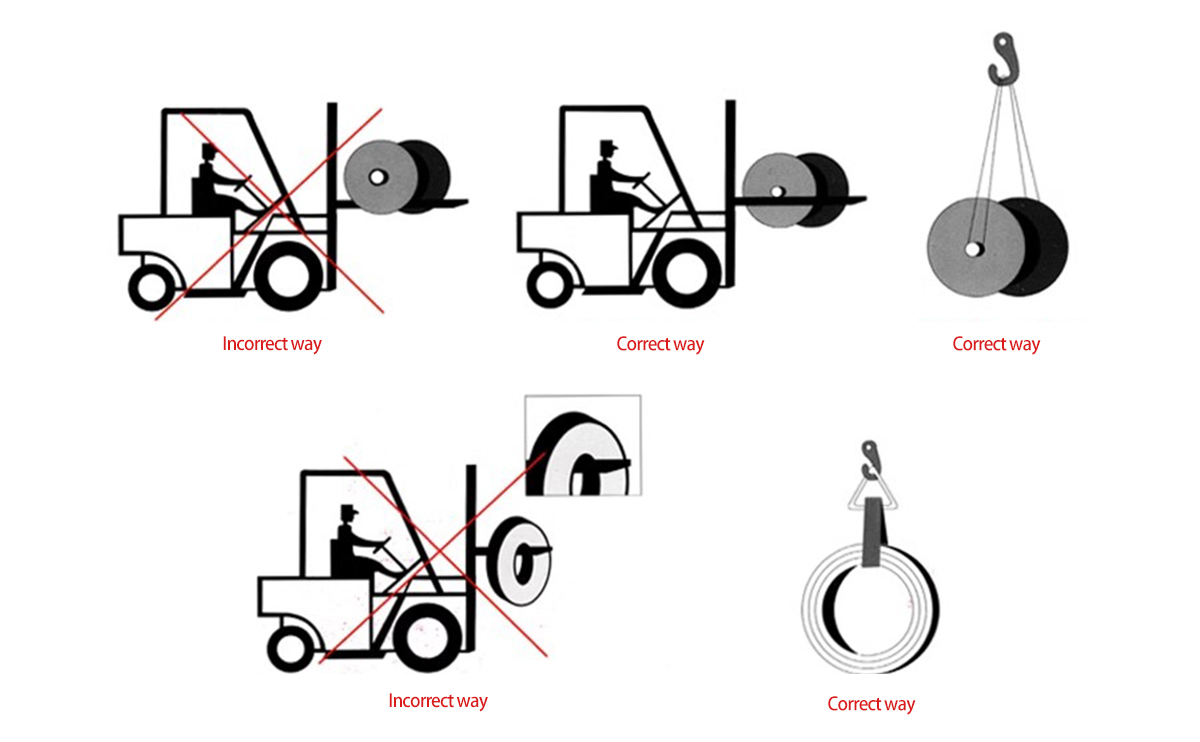

c) When using a forklift to transport wooden discs and reels, you can only shovel the reel discs or use lifting equipment; when transporting coiled wire ropes without wooden discs, you must use suspension hooks and slings or other suitable lifting devices. , do not directly touch the wire rope to prevent damage to the wire rope.

Rope scraping diagram:

Install

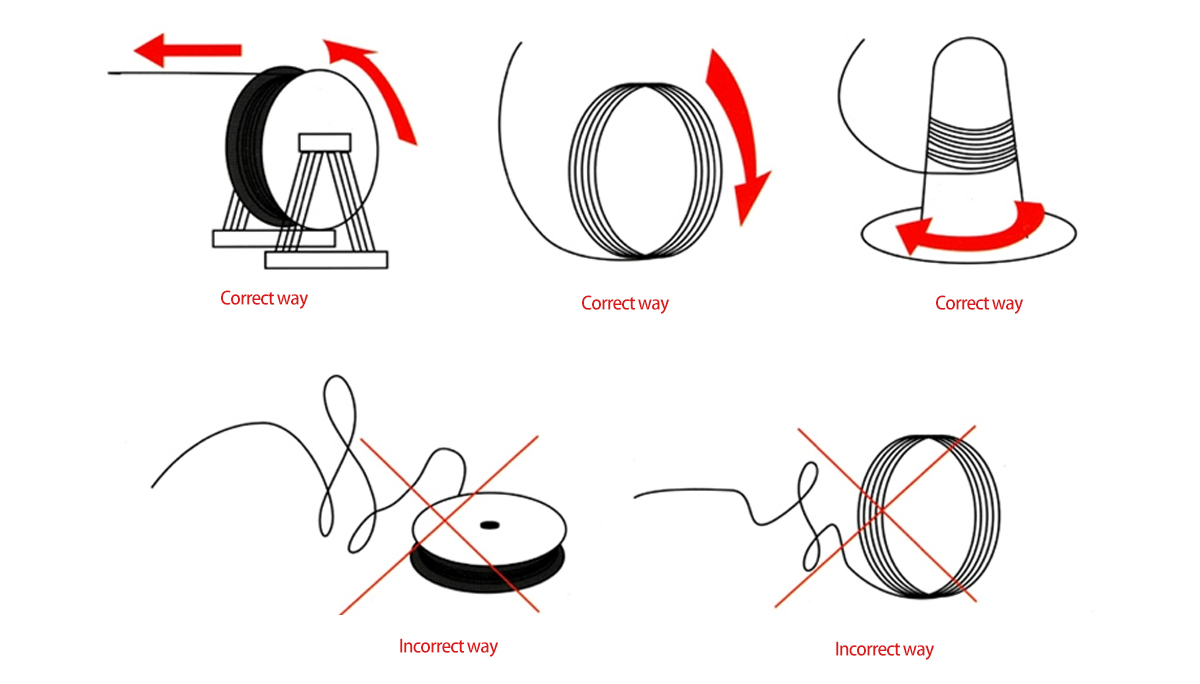

a) Correct and standardized operating methods should be adopted during the installation process of the wire rope to avoid artificial twisting, loosening, etc., which will shorten the service life of the wire rope.

Wire rope pay-out diagram

b) Put the rope head of the rope during the installation of the wire rope should be fixed on the heavy -dote (dedicated line rack) or load the rope head to prevent the wire rope from rotating to generate internal stress. Avoid the phenomenon of pine stocks and lanterns due to internal stress release during installation of the elevator, so that the wire rope is discarded before the early report.

Maintain

a) Since the storage conditions of the wire rope cannot be determined and the time interval from storage to installation, it is recommended to check it before and after the installation of the wire rope to determine whether it is necessary to lubricate again;

b) After the elevator runs, the lubricating oil contained in the wire rope will gradually decrease, causing the wear of the wire rope and rope wheel to rust and the wire rope. Therefore, apply lubricating oil regularly. (Please use the company's dedicated to maintain oil, such as the sales of the company when maintaining the demand.) When the following situations appear, the elevator wire rope should be lubricated again in time: 1) The surface of the steel wire rope is dry and the lubricating oil cannot be touched; 2) Rust spots appear on the surface of the wire rope; 3) The elevator runs 200,000 times per lift.

Post time: Dec-25-2023