- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

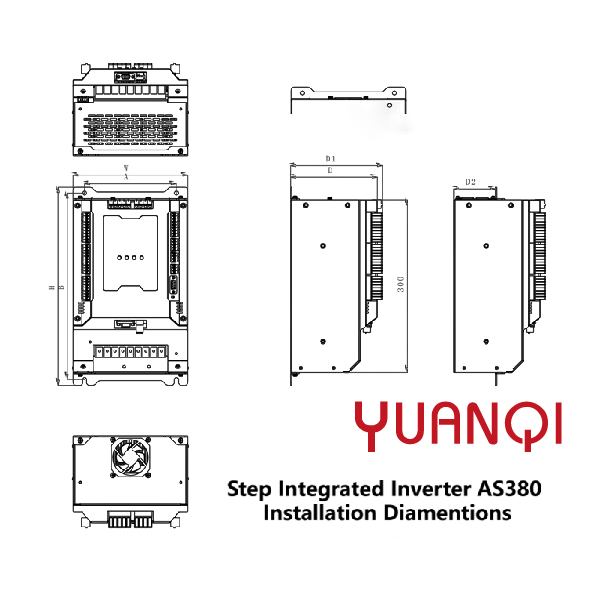

STEP elevator all-in-one inverter AS380 4T07P5/4T0011/4T0015/4T18P5 Flashable protocol

Product Display

Specifications

| AS380 | A (mm) |

B (mm) |

H (mm) |

W (mm) |

D (mm) |

Installation hole diameter Φ(mm) |

Install | Tightening torque (Nm) |

Weight (kg) |

||

| bolt | nut | washer | |||||||||

| 2S01P1 | 100 | 253 | 265 | 151 | 166 | 5.0 | 4M4 | 4M4 | 4Φ4 | 2 | 4.5 |

| 2S02P2 | |||||||||||

| 2S03P7 | |||||||||||

| 2S05P5 | 165.5 | 357 | 379 | 222 | 192 | 7.0 | 4M6 | 4M6 | 4Φ6 | 2 | 8.2 |

| 2T05P5 | |||||||||||

| 2T07P5 | |||||||||||

| 2T0011 | |||||||||||

| 2T0015 | 165 | 440 | 465 | 254 | 264 | 7.0 | 10.3 | ||||

| 2T18P5 | |||||||||||

| 2T0022 | |||||||||||

| 4T02P2 | 100 | 253 | 265 | 151 | 166 | 5.0 | 4M4 | 4M4 | 4Φ4 | 2 | 4.5 |

| 4T03P7 | |||||||||||

| 4T05P5 | |||||||||||

| 4T07P5 | 165.5 | 357 | 379 | 222 | 192 | 7.0 | 4M6 | 4M6 | 4Φ6 | 3 | 8.2 |

| 4T0011 | |||||||||||

| 4T0015 | 165.5 | 392 | 414 | 232 | 192 | 10.3 | |||||

| 4T18P5 | |||||||||||

| 4T0022 | |||||||||||

| 4T0030 | 200 | 512 | 530 | 330 | 290 | 9.0 | 4M8 | 4M8 | 4Φ8 | 6 | 30 |

| 4T0037 | 9 | ||||||||||

| 4T0045 | 200 | 587 | 610 | 330 | 310 | 10.0 | 42 | ||||

| 4T0055 | 4M10 | 4M10 | 4Φ10 | 14 | |||||||

| 4T0075 | 200 | 718 | 730 | 411 | 411 | 10.0 | 50 | ||||

Features

A) It is an organic combination of elevator control and drive. The entire device has a compact structure, small size and less wiring, high reliability, easy operation, and more economical;

B) Dual 32-bit embedded microprocessors jointly complete the elevator operating functions and motor drive control;

C) Redundant safety design, dual safety protection of the control processor and drive processor to achieve the strongest safety guarantee for elevator operation;

D) The anti-interference capability design exceeds the highest level of industrial design requirements;

E) Full CAN bus communication makes the wiring of the entire system simple, with strong data transmission capability and high reliability;

F) Adopt advanced direct parking technology to make the elevator run more efficiently;

G) It has rich and advanced elevator operation functions, which can fully meet the various needs of customers;

H) It has advanced group control function, which not only supports the traditional group control method of up to eight stations, but also supports the novel destination layer allocation group control method;

l) Using advanced vector control technology, the motor has excellent speed regulation performance and achieves the best comfort;

J) It has good versatility and is suitable for both synchronous motors and asynchronous motors;

K) The newly created no-load sensor starting compensation technology enables the elevator to have excellent starting comfort without installing a weighing device;

L) Incremental ABZ encoder can be used to realize synchronous motor control, and no-load sensor starting compensation technology can also be used to achieve excellent starting comfort;

M) New PWM dead zone compensation technology, effectively reducing motor noise and motor losses;

N) Dynamic PWM carrier modulation technology, effectively reducing motor noise;

O) Synchronous motors do not require encoder phase angle self-tuning;

P) If the motor parameters are set accurately, the asynchronous motor does not need motor parameter self-learning. If the precise motor parameters cannot be known on site, a simple static motor self-learning method can be used to allow the system to automatically obtain the accurate parameters of the motor without the need for complicated work such as lifting the car;

Q) The hardware adopts the 6th generation new module, which can withstand junction temperature up to 175℃, has low switching and turn-on losses, and extends the service life.