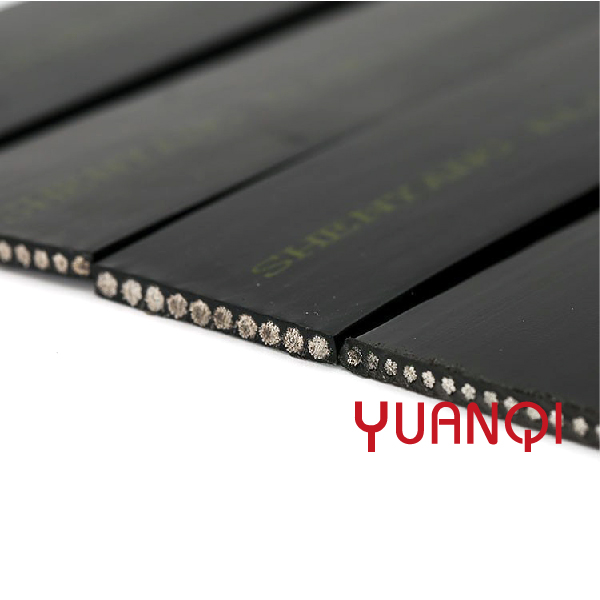

AAA717X X1 AM2 AP2 AJ2 AD1 W1 Elevator Traction Cable Steel Belt Elevator Steel Belt AAA717W1

Product Display

Specifications

| Specification/ Piece number | Width/mm | Thickness/mm | Number of wire core | Pull | Appearance |

| AAA717X1 | 30 | 3 | 12 | 32KN | two side with out line |

| AAA717W1 | 30 | 3 | 12 | 32KN | one side with line 'V' type,the other side without line |

| AAA717AM2 | 30 | 3.2 | 10 | 43KN | two side with out line |

| AAA717AP2 | 30 | 3.2 | 10 | 43KN | two side with out line |

| AAA717AJ2 | 30 | 3.2 | 10 | 43KN | two side with out line |

| AAA717AD1 | 60 | 3 | 24 | 64KN | two side with out line |

| AAA717R1 | 60 | 3 | 24 | 64KN | one side with line 'W' type,the other side without line |

| AAA717AJ1 | 25 | 3.2 | 8 | 32KN | two side with out line |

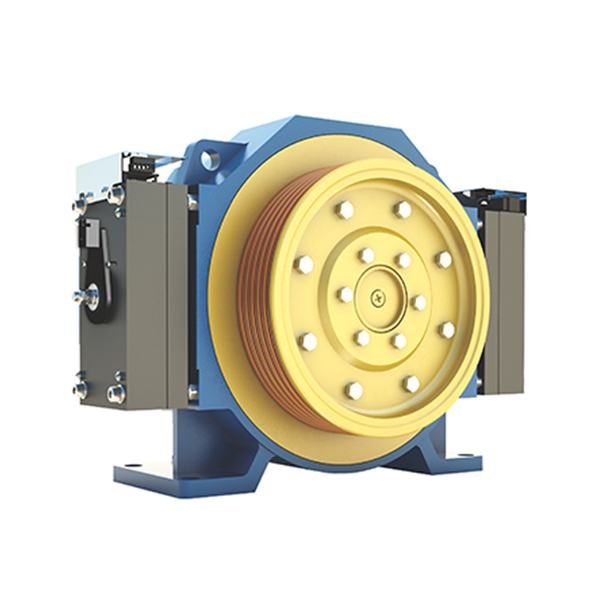

The electric steel belt traction system is a new generation of machine room-less elevator traction system designed based on a flat composite transmission belt, its traction machine and safety monitoring device. Compared with the traditional wire rope traction system, the new steel belt traction system has revolutionary changes in investment, space utilization, operating costs, and reliability.

Compared with the traditional steel wire rope traction system, the composite steel belt traction system relies on the more flexible characteristics of the steel belt (minimum bending radius 80-100mm), making it possible to make the traction machine, reverse sheave and other components more compact. The polymer material covering the outer layer of the composite steel strip also provides effective protection for the internal steel wire rope, thereby creating revolutionary value for end customers.