STEP ilifti inverter yonke-in-one AS380 4T07P5/4T0011/4T0015/4T18P5 Iphrothokholi eFlashable

Isibonisi somkhiqizo

Imininingwane

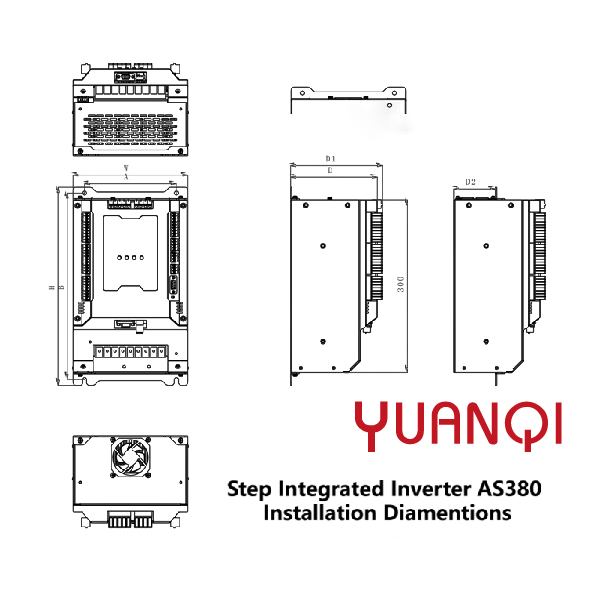

| AS380 | A (mm) | B (mm) | H (mm) | W (mm) | D (mm) | Ukufakwa kwembobo ububanzi Φ(mm) | Faka | I-torque yokuqinisa (Nm) | Isisindo (kg) | ||

| ibhawodi | nati | owasha | |||||||||

| I-2S01P1 | 100 | 253 | 265 | 151 | 166 | 5.0 | 4m4 | 4m4 | 4Φ4 | 2 | 4.5 |

| I-2S02P2 | |||||||||||

| 2S03P7 | |||||||||||

| 2S05P5 | 165.5 | 357 | 379 | 222 | 192 | 7.0 | 4m6 | 4m6 | 4Φ6 | 2 | 8.2 |

| 2T05P5 | |||||||||||

| 2T07P5 | |||||||||||

| 2T0011 | |||||||||||

| 2T0015 | 165 | 440 | 465 | 254 | 264 | 7.0 | 10.3 | ||||

| 2T18P5 | |||||||||||

| 2T0022 | |||||||||||

| 4T02P2 | 100 | 253 | 265 | 151 | 166 | 5.0 | 4m4 | 4m4 | 4Φ4 | 2 | 4.5 |

| 4T03P7 | |||||||||||

| 4T05P5 | |||||||||||

| 4T07P5 | 165.5 | 357 | 379 | 222 | 192 | 7.0 | 4m6 | 4m6 | 4Φ6 | 3 | 8.2 |

| 4T0011 | |||||||||||

| 4T0015 | 165.5 | 392 | 414 | 232 | 192 | 10.3 | |||||

| 4T18P5 | |||||||||||

| 4T0022 | |||||||||||

| 4T0030 | 200 | 512 | 530 | 330 | 290 | 9.0 | 4m8 | 4m8 | 4Φ8 | 6 | 30 |

| 4T0037 | 9 | ||||||||||

| 4T0045 | 200 | 587 | 610 | 330 | 310 | 10.0 | 42 | ||||

| 4T0055 | 4M10 | 4M10 | 4Φ10 | 14 | |||||||

| 4T0075 | 200 | 718 | 730 | 411 | 411 | 10.0 | 50 | ||||

Izici

A) Kuyinhlanganisela yezinto eziphilayo zokulawula ikheshi nokushayela. Yonke idivayisi inesakhiwo esihlangene, usayizi omncane kanye nezintambo ezincane, ukwethembeka okuphezulu, ukusebenza okulula, futhi ukonga okwengeziwe;

B) Ama-microprocessors ashumekwe we-Dual 32-bit aqedela ngokuhlanganyela imisebenzi ye-elevator kanye nokulawulwa kwe-motor drive;

C) Idizayini yokuphepha engafuneki, ukuvikela okubili kokuphepha kwephrosesa yokulawula kanye nephrosesa yokushayela ukuze kuzuzwe isiqinisekiso esiqine kakhulu sokuphepha sokusebenza kwekheshi;

D) Idizayini yamandla okumelana nokuphazamiseka idlula izinga eliphezulu lezidingo zedizayini yemboni;

E) Ukuxhumana okugcwele kwebhasi le-CAN kwenza izintambo zalo lonke uhlelo zibe lula, ezinekhono eliqinile lokudlulisa idatha nokuthembeka okuphezulu;

F) Yamukela ubuchwepheshe obuphambili bokupaka izimoto ukuze wenze ilifti isebenze kahle;

G) Inemisebenzi ecebile nethuthukisiwe yokusebenza kwekheshi, engahlangabezana ngokugcwele nezidingo ezahlukahlukene zamakhasimende;

H) Inomsebenzi othuthukisiwe wokulawula iqembu, ongasekeli nje kuphela indlela yokulawula yeqembu efinyelela eziteshini eziyisishiyagalombili, kodwa futhi esekela indlela yokulawula yeqembu inoveli yendawo okuyiwa kuyo;

l) Isebenzisa ubuchwepheshe obuthuthukisiwe bokulawula i-vector, injini inokusebenza okuhle kakhulu kokulawula isivinini futhi ifinyelela ukunethezeka okungcono kakhulu;

J) Inokuguquguquka okuhle futhi ilungele womabili amamotho ahambisanayo namamotho asynchronous;

K) Inzwa esanda kwakhiwa engenamthwalo iqala ubuchwepheshe besinxephezelo yenza ilifti ibe nokunethezeka okuhle kakhulu kokuqala ngaphandle kokufaka idivayisi yokukala;

L) Isishumeki se-ABZ esikhuphukayo singasetshenziswa ukubona isilawuli semoto esivumelanayo, kanye nobuchwepheshe besinxephezelo senzwa yokungalayishi futhi bungasetshenziswa ukuzuza ukunethezeka kokuqala okuhle kakhulu;

M) Ubuchwepheshe obusha bokunxeshezelwa kwendawo efile ye-PWM, enciphisa ngempumelelo umsindo wezimoto nokulahleka kwezimoto;

N) Ubuchwepheshe bokumodula kwesithwali se-Dynamic PWM, okwehlisa ngempumelelo umsindo wezimoto;

O) Amamotho e-synchronous awadingi ukuzishuna kwe-engeli yesigaba se-encoder;

P) Uma ipharamitha yemoto isethwe ngokunembile, i-asynchronous motor ayidingi ukuzifundela kwepharamitha yemoto. Uma imingcele yemoto enembile ingakwazi ukwaziwa esizeni, indlela elula yokuzifundela imoto emile ingasetshenziswa ukuvumela uhlelo ukuthi luzitholele ngokuzenzakalelayo imingcele enembile yemoto ngaphandle kwesidingo somsebenzi oyinkimbinkimbi njengokuphakamisa imoto;

Q) Izingxenyekazi zekhompuyutha zamukela imojuli entsha yesizukulwane sesithupha, ekwazi ukumelana nezinga lokushisa elifinyelela ku-175℃, inokushintsha okuphansi nokulahlekelwa kokuvula, futhi inwebe impilo yesevisi.